Industrial Facility Noise Reduction

Industrial Facilities

Industrial Facility Noise Reduction – With more and more industrial facilities being built, the need to control the noise transmissions given off near and around parts of these facilities is ever growing.

The first and most important reason to control these noisy environments is for the safety of the workers and management at the sites. If workers misinterpret a directive, or are unsure of directions, an injury is imminent.

The next issue is productivity. It is medically proven that the human body is adversely affected by long durations of extreme sound pressure or noise. our nervous systems cannot handle the stress this type of fatigue causes. A worker who is stressed or fatigued is more likely to make a mistake or not work up to full potential.

The third area of concern involves surrounding residential areas. The noise from a twenty-four hours a day facility could and would drive someone crazy. If the noise level is too much for surrounding communities, they will complain and get the government involved. If this happens, it may also cause shut downs and lack of productivity. At the end of the day, all of the above scenarios spell loss of revenue.

Automotive Manufacturing Facilities

The different sections of an automotive manufacturing facility vary dramatically in terms of noise exposure. From water leak inspection, vibration noise inspection, assembly machines, RPM tests, wind tunnel tests and a myriad of other work stations around the plant, noise is quite apparent.

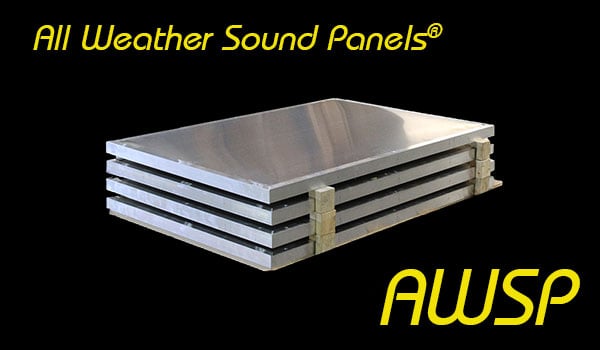

Acoustiblok has remedied the noise in these types of facilities with our patented IAWSP’s. Our “Industrial All Weather Sound Panels” are great for enclosures, barrier systems, and testing lanes. They can also be placed around workstations in a permanent manner or on movable caster assemblies.

Acoustiblok can work directly with your facilities managers to create custom packages perfect for your specific area of the plant. These packages are prepared like an erector set of sorts. They come labeled with a build document and layout plan.

If you need to get the noise exposure issues under control at your facility Acoustiblok has the solutions. Pleas feel free to contact us so we can have one of our automotive manufacturing specialists help you with a package for your plant.

Bottling Plant Facilities

Ah, that wonderful sound of popping the top off of an ice-cold beer. It’s quite a different experience before that top gets put on that bottle. One of the nosiest places you could work is near the bottling line of a brewery. The clink and clank of the bottles as they travel down the conveyors is far from quiet! And that’s just one area with a lot of noise.

It seems that the noise comes from everywhere due to all the hard surfaces of the plant. The labelers are loud, the fillers are loud and all of this in a building with reflective surfaces everywhere. It makes for a perfect storm of work related noise exposure.

The good news is Acoustiblok has got you covered. Our patented IAWSP’s, Quiet-Clouds, and Acoustifence have no problem with this harsh environment. Our panels and clouds have specific sealed liners to protect them from cleaners, moisture and particulate scattering. They can be arranged to accommodate workflows and are easy for facility staffers to install.

Our Quiet Clouds have an NRC of 1.0, can be powder coated, hung vertically or horizontally to reduce the reflection time within the facility. Our IAWSP’s have an STC of 30 dba and an NRC of 1.0. They can be outfitted with casters for equipment serviceability or permanently mounted as barrier structures.

So if you need sustainable solutions for a long-term facility, please contact us so you can speak with one of our brewery specialists.

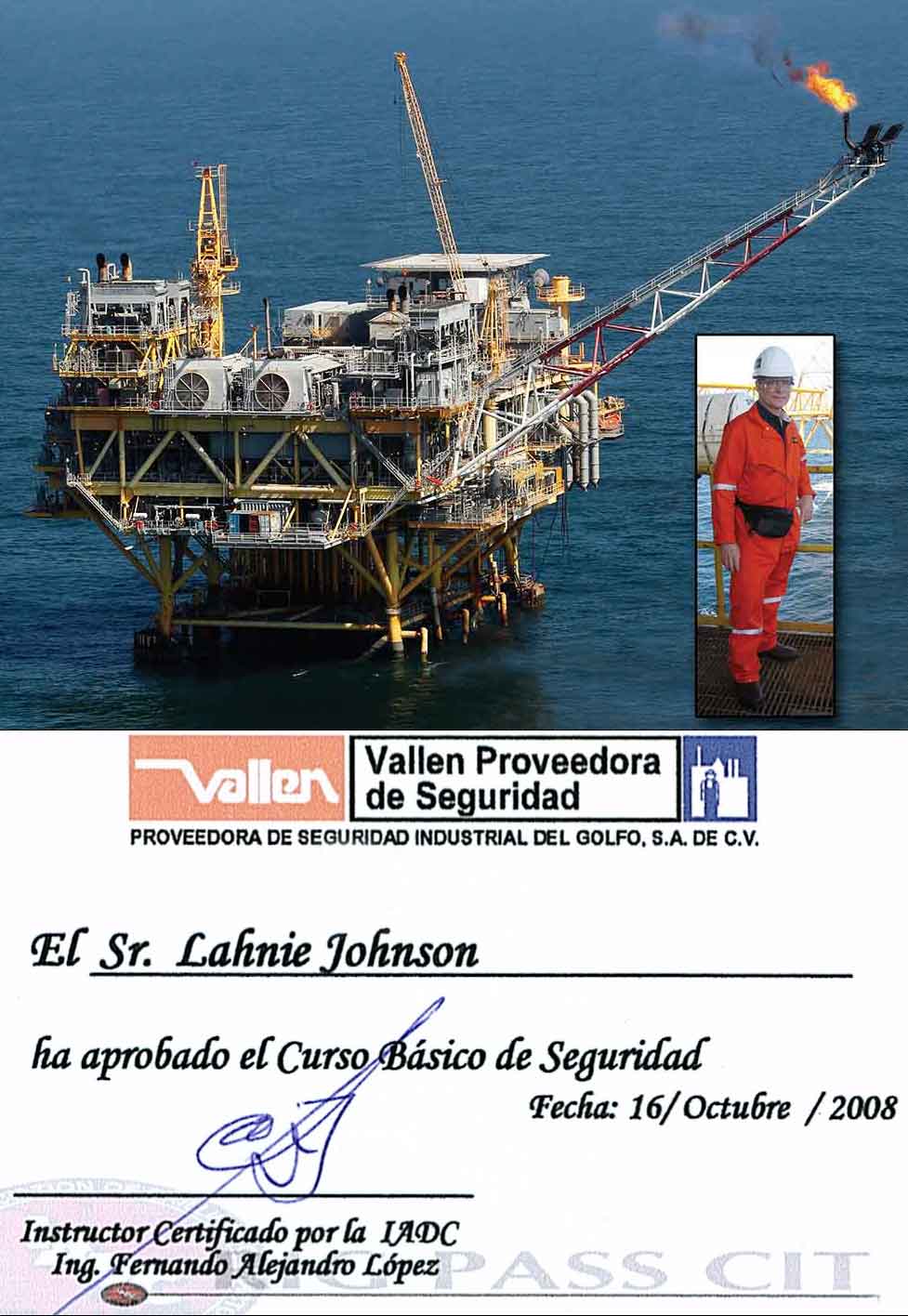

Offshore Exploration

One of the most dangerous places in the world to work is on an off shore oil rig. The environment is harsh, the work is hard and it just so happens to be one of the loudest places on Earth. So where do we start with this loud and hazardous work environment? First, let’s understand how important it is for all the workers on the rig to be on their toes, ALL the time. Heavy machinery, combustible gases, poisonous gases, open walkways (15-30m above the ocean’s surface), and some of the loudest (105-135dB) noises imaginable.

The gas burn off nozzles make a noise that never goes away, 24 hours a day, 7 days a week, so acoustical barriers (all weather sound panels) should be in place to reduce this overwhelming and constant noise level. These noises are particularly intense in the frequency ranges that we as humans hear very efficiently (800Hz – 6.3 kHz), so they seem even louder to us than they are.

Another contributor is the high pressure gas line that feeds the burn off nozzles. This is also creates a constant noise and never shuts down. The solution for this is our Acoustiblok barrier material. This gets treated as a pipe wrap, layering Acoustiblok until the level of attenuation is reached to meet the criteria for the surrounding work area. Our pipe wraps have made reductions of more than 28dB with just a two layers of material combined. Wraps will react differently based on the frequencies being emitted. An acoustical measurement of the noise spectrum should always be performed by an acoustician or qualified acoustical consultant to achieve the highest level of results.

Distribution/Shipping Facilities

Trucks, tractor-trailers, forklifts and all kinds of noises exist at distribution centers. This is fine if the distribution center is out in the middle of nowhere. But if it’s in close proximity to a residential neighborhood, that noise is a problem at 2:00 AM when people are trying to sleep.

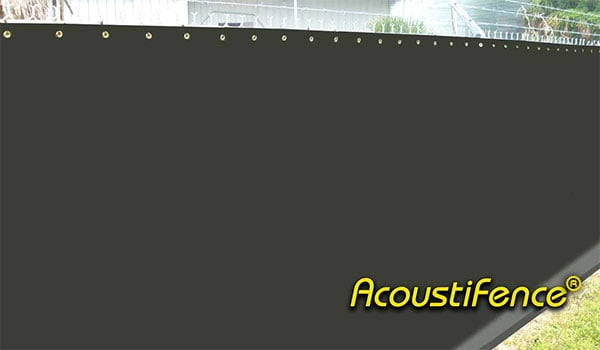

Acoustiblok has been extremely successful with these types of locations. Our AF-6 (Acoustifence) is a great material to supply a large reduction in the noise that tends to make it into surrounding communities. AF-6 has an STC 28, making it an incredible line of sight noise barrier, with nearly endless applications.

AF-6 is UV tolerant, incorporates our proprietary industrial reinforcement system and can have a horizontal or vertical orientation. AF-6 can be a temporary or permanent solution. Our unique installation system prevents large gaps between each section of AF-6.

So if you need help in reducing your company’s noise impact on the community, please feel free to contact one of our specialists in this industry.

Trucks, tractor-trailers, forklifts and all kinds of noises exist at distribution centers. This is fine if the distribution center is out in the middle of nowhere. But if it’s in close proximity to a residential neighborhood, that noise is a problem at 2:00 AM when people are trying to sleep.

Trucks, tractor-trailers, forklifts and all kinds of noises exist at distribution centers. This is fine if the distribution center is out in the middle of nowhere. But if it’s in close proximity to a residential neighborhood, that noise is a problem at 2:00 AM when people are trying to sleep.